What do you see in the future?

A self-driving car in every driveway? Alexa making you french toast every morning? A Bitcoin piggy bank for the kids?

Patrick Brown of UC Davis sees a future that holds a better way of growing almonds, one that cuts down on dust in the air, reduces the risk of navel orangeworm and hull rot, and gives growers many more opportunities to improve soil and tree health.

He’s done research on both sides of the Pacific Ocean, looking for the solutions to the most pressing issues facing almond growers in Australia and California, and how they can be solved.

“We’ve approached this like a business case study,” Brown explained by phone. “You look at challenges, you look at threats, and you look at opportunities. Dust is probably the biggest threat to the industry...the issue of dust generated during almond harvest has been on the minds of the almond industry for many years and a long-term solution is clearly required.”

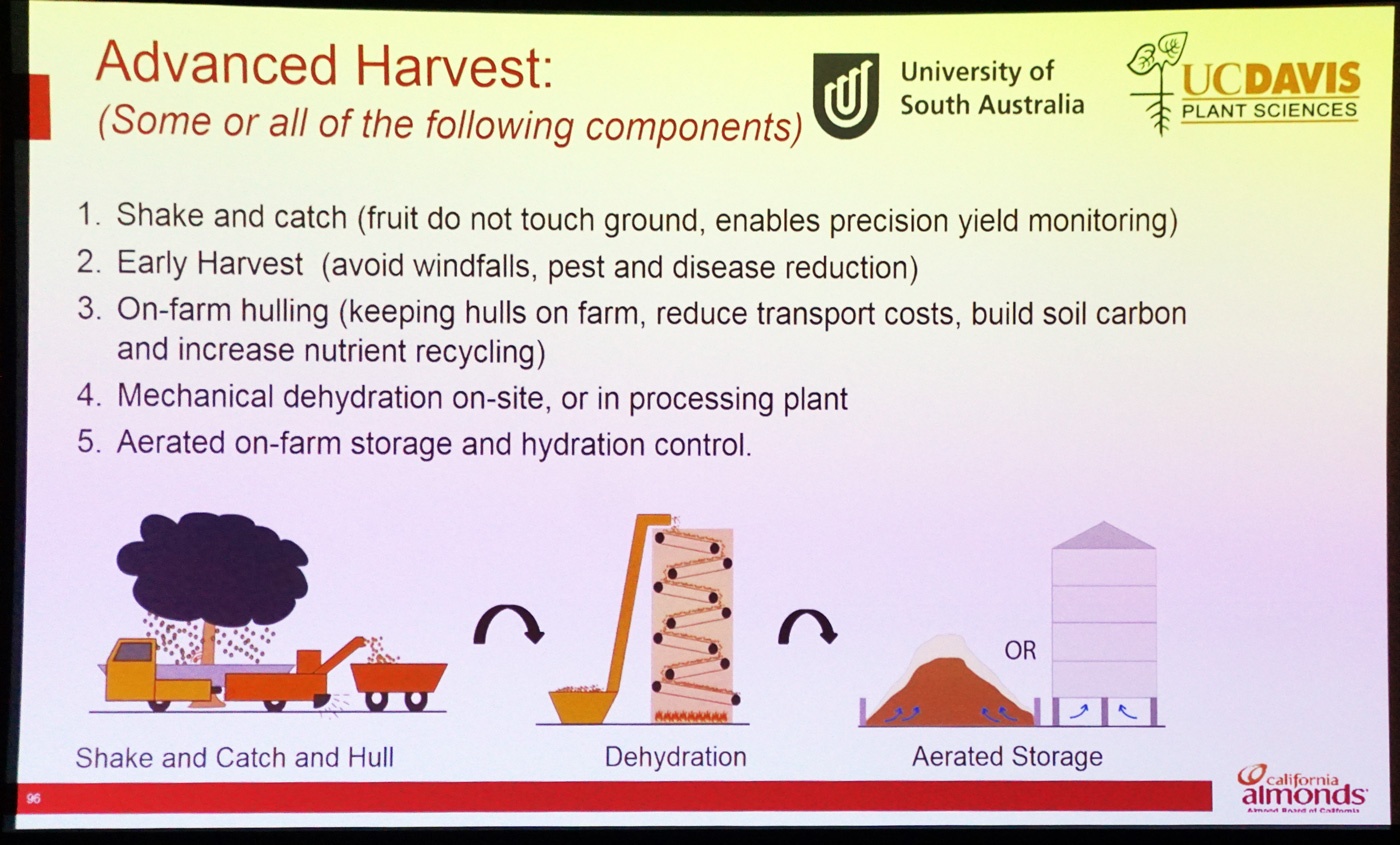

The solutions Brown envisions can be called “Advanced Harvest,” and include a set of changes that work together: harvesting about three weeks earlier than current practice, catching the nuts so they do not touch the orchard floor, followed by hulling and drying on the farm.

“The current harvest practices were designed to maximize on-tree drying of the nuts and use sunlight in the orchard to dry the nuts,” Brown said. “That on-tree extended drying, however, introduces greater potential for navel orangeworm, hull rot, and aflatoxin while limiting the options that growers have for managing their orchard floor.”

A slide from a presentation by Patrick Brown at the Almond Conference.

What’s needed to usher in this change in orchard design? In part, it’s new machinery to catch harvest and to hull and dry the fruit.

“It’s a chicken and an egg issue,” Brown said. “It’s not possible to ask people to early harvest unless they have the ability to catch those nuts and take them off the orchard.”

But, he said, the first generation of machinery specifically designed for shake and catch almond orchards is already in use in Spain and has been used to a limited extent in California. More development is clearly on its way.

For their part, almond growers are making changes already as well.

“As a first step, for example, growers planting new orchards could choose to graft trees higher to provide more room for shake and catch equipment,” Brown said. “There are a number of growers who are planting new orchards with a higher crotch, instead of 24 inches from the ground, to 30 or 33 inches from the ground, to facilitate catch and harvest.”

Do growers lose anything on the yield side by adopting the new practices? Brown told growers at the Almond Conference in Sacramento that early harvest doesn’t present much downside because once fruit have progressed to the B3 stage three weeks before traditional harvest dates, full nut size is achieved.

Beyond dust reduction and pest avoidance, Brown sees a bright future for growers, who will benefit from early harvest orchards in a number of ways.

“By recycling hulls in the field, you can save up to 40% of your annual nitrogen demand..and 80% of your potassium, and you will be providing greater than 10,000 lbs of organic matter,” Brown said. “The traditional harvesting system currently implemented in California also impedes the use of ground covers, and compost, or the return of organic matter to the orchard floor, like shells and hulls. Harvesting practices that do not rely on the nut being on the orchard floor will therefore help us improve soil health and long term orchard productivity.”

Already, hullers and shellers have approached him to talk about a new potential role of this change in harvesting practice in the orchard, Brown said, and he's spoken with a major grower that's begun planting orchards with the new design in Australia.

“I think the vision for this is in the five to ten years, you could see this increasingly adopted by the industry,” Brown said.